As the world moves towards a greener future, China has set ambitious "Dual Carbon" targets, which have propelled the photovoltaic (PV) power generation industry into an era of unprecedented growth and potential. The State Council's plan for achieving peak carbon emissions by 2030 envisions an installed capacity of wind and solar power exceeding 1.2 billion kilowatts. However, as PV installations become more widespread, users are encountering penalties on their electricity bills due to poor power factor performance, resulting in significant financial losses.

According to the 'Power Factor Adjustment Tariff Method', industrial consumers must maintain an average monthly power factor above 0.9 to avoid penalties. This ratio is determined by dividing the active energy consumption by the apparent energy consumption. Traditional capacitor banks used for reactive power compensation can usually keep the power factor within compliance limits. However, the addition of PV systems, which primarily supply active power, reduces the grid's active power draw without affecting the reactive power component, thus lowering the overall power factor. When PV generation matches or exceeds load consumption, active power from the grid can approach zero, significantly impacting the power factor.

The conventional approach to reactive power compensation using capacitor banks is characterized by slow response times and limited precision. In scenarios without PV installations, these drawbacks are less critical due to substantial active power consumption from the grid. However, with PV installations supplying large amounts of active power, reducing the grid's active power draw, the remaining uncompensated reactive power becomes more significant. This issue is exacerbated when PV generation surpasses the site's load requirements, leading to reverse active power flow and potentially disabling some reactive power controllers, further deteriorating the power factor.

For sites solely powered by PV, where active power consumption is minimal, it is essential not only to manage the low-voltage side reactive power but also to address the transformer-generated reactive power on the high-voltage side to ensure compliance with power factor standards.

To tackle the low power factor at PV sites, comprehensive reactive power management is required. The solution lies in deploying advanced Static Var Generators (SVGs), which utilize state-of-the-art power electronics and automatic control technologies. SVGs operate in parallel with the grid, continuously monitoring system currents via current transformers and injecting compensatory currents that negate the reactive power component, effectively performing reactive power compensation.

The three-level structure of SVGs, combined with high-performance IGBT modules, achieves an equivalent switching frequency of over 20kHz, ensuring rapid response times within 5ms and a reactive power compensation efficiency exceeding 99%. Such capabilities make SVGs highly effective in addressing the reactive power challenges faced by PV installations.

In typical retrofit projects, existing capacitor banks can be augmented with SVG modules to compensate for any residual reactive currents left unaddressed by the capacitors. Careful consideration must be given to the positioning of sampling current transformers for both the capacitor controller and the SVG to ensure accurate measurement and proper coordination between the two devices.

The sizing of the added SVG capacity should be based on the magnitude of residual reactive power at the site, which can be assessed through either readings from the reactive power controller or on-site power quality testing. It is advisable to select SVG capacities with a margin for future adjustments.

6.Application Case Study

Shanghai Boyang New Energy Technology Co., Ltd. is a comprehensive energy service company with extensive experience in energy conservation retrofits, power engineering, clean energy generation, multi-energy complementation, and micro-energy network construction. After installing a photovoltaic (PV) power generation system at a factory of CRRC in Xi'an, the site experienced a drop in its power factor, leading to electricity penalty charges.

Initial Solution Implementation

To address the issue of power penalties, a 200 kvar Static Var Generator (SVG) reactive power compensation cabinet was installed on-site to manage the low-voltage side reactive power. Following this intervention, the power factor significantly improved, and the site no longer incurred any electricity penalties.

Recurrence of Issue

Half a year later, the customer reported that power penalties had reappeared. Upon investigation, it was revealed that the production load had ceased entirely, transforming the site into a pure PV power generation state with a dramatic reduction in active power consumption. Despite full compensation for low-voltage side reactive power, the inherent reactive power generated by the transformer during operation meant that the high-voltage side power factor still did not meet the required standards.

Advanced Solution Implementation

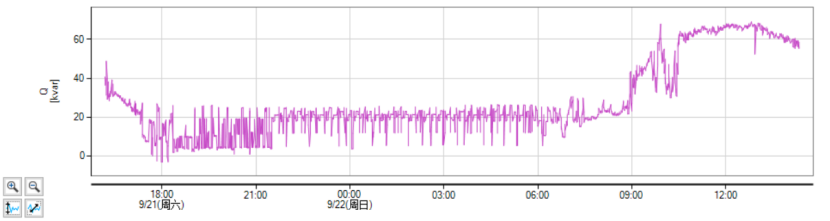

To tackle the reactive power generated by the transformer on the high-voltage side, we conducted an analysis of the high-voltage side power quality. Based on the findings, we optimized the SVG's compensation strategy and added functionality to compensate for high-voltage side reactive power. This adjustment effectively addressed the reactive power issues originating from the transformer's high-voltage side.

Results After optimizing the SVG, there was a noticeable decrease in high-voltage side reactive power, and the power factor increased from 0.77 to 0.94, indicating a successful compensation effect. This case study highlights the importance of addressing both low- and high-voltage side reactive power challenges in PV installations, especially when transitioning to a pure PV power supply scenario. The application of advanced technologies like SVGs can provide effective solutions to maintain optimal power factors and avoid unnecessary financial penalties.

After optimizing the SVG, there was a noticeable decrease in high-voltage side reactive power, and the power factor increased from 0.77 to 0.94, indicating a successful compensation effect. This case study highlights the importance of addressing both low- and high-voltage side reactive power challenges in PV installations, especially when transitioning to a pure PV power supply scenario. The application of advanced technologies like SVGs can provide effective solutions to maintain optimal power factors and avoid unnecessary financial penalties.

Subscribe to us to enjoy event prices and get some of the best prices.

IPv6 network supported

IPv6 network supported