Why Reactive power compensation is necessary on solar site?

Backgaround

With the development of the economy and the improvement of green energy awareness, more and more regions are using clean energy and installing a large number of solar power generation equipment. With the widespread use of photovoltaic power generation, many users have found that there are power adjustment fees, namely power fines, in the electricity bill, and the amount of fines is relatively large, causing huge losses to users.

Problem analysis

According to China's "Power Factor Adjustment Electricity Tariff Measures", for general industrial users, the monthly average power factor must reach 0.9 or above, otherwise electricity fines will be incurred. The average power factor is calculated based on the user's monthly practical active and reactive power consumption, and the calculation formula is as follows.

Power factor=active energy/total energy

In general, capacitor compensation cabinets are installed on site for reactive power compensation, so the reactive power consumption is small and the power factor can reach 0.9 or above, without generating power fines. After increasing photovoltaic power generation, as photovoltaic power generation is all active electricity, it will lead to a decrease in active electricity at the metering meter of the power company, while reactive electricity will not decrease, resulting in a decrease in power factor. When the photovoltaic power generation is equal to or greater than the load electricity consumption, the active energy at the metering meter is 0, which will result in a small total active energy per month and a low monthly power factor.

Industry Status

At present, most factories generally use traditional capacitor switching for reactive power compensation, which has slow response speed and low compensation accuracy. When photovoltaic power is not installed on site, due to the huge consumption of active power in the power grid, although the use of capacitor compensation has certain drawbacks, which may result in the remaining part of reactive power being unable to be fully compensated, it is insignificant compared to the active power consumed by the power grid, and can still ensure that the power factor reaches 0.9 or above.

However, when photovoltaic power generation is installed on site, it provides a large amount of active electricity, leading to a sharp decrease in the active electricity consumed by the load from the power grid. At this time, the remaining reactive electricity compensated by the capacitor will become more important compared to the active electricity consumed by the power grid; Even when the photovoltaic power generation exceeds the power consumption of the load, the active power consumption of the power grid is 0, and the active power is reversed. Some reactive power compensation controllers may even fail to work properly, leading to a further increase in reactive power and a further decrease in power factor.

Solutions

To solve the problem of low power factor in photovoltaic field, it is necessary to ensure that the on-site reactive power is completely controlled. Therefore, a new type of power electronic active compensation device SVG static reactive power generator must be used for reactive power control. SVG applies the most advanced power electronics technology and automatic control technology, which are connected in parallel in the power grid. It samples the system current in real-time through current transformers, extracts the reactive components, and emits currents of equal magnitude and opposite phase to offset the reactive current in the power grid, thus achieving the goal of reactive compensation.

Field application

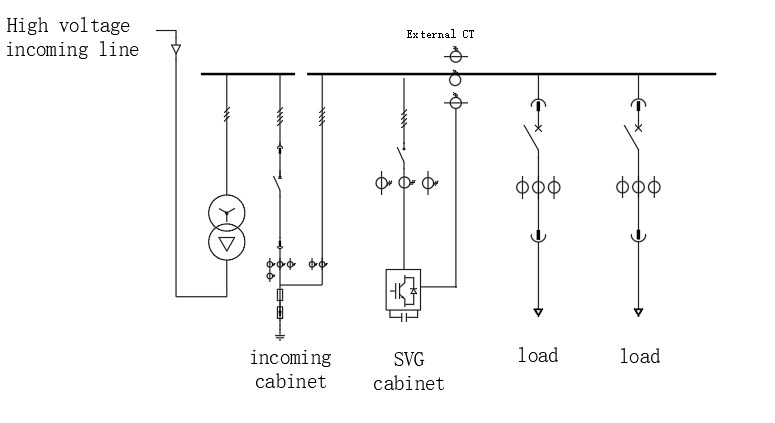

For general on-site renovation projects, it is recommended to add an SVG module on top of the existing capacitor cabinet compensation on site, and use SVG to compensate for the remaining reactive current of the capacitor compensation, thus achieving the goal of reactive power compensation. The schematic diagram of on-site wiring is as follows

The SVG capacity is generally configured based on the size of on-site reactive power. The reactive power size on the reactive power controller can be viewed, and the reactive power compensation capacity can be confirmed through on-site power quality testing. When selecting SVG compensation capacity, it is generally necessary to consider leaving a certain margin.

YTPQC-SVG

SVG adopts a three-level structure and high-performance IGBT power module, with an equivalent switching frequency of over 20kHz. Therefore, SVG can quickly compensate for reactive power, with a response speed of less than 5ms and a reactive power compensation rate of over 99%, effectively solving the problem of reactive power compensation in photovoltaic field.VG (Static Var Generator) is a type of power electronic device used to compensate for reactive power in a power system. It works by generating or absorbing reactive power, depending on the needs of the system. The SVG can be used to compensate for both capacitive and inductive reactive power, but it is most commonly used to compensate for capacitive reactive power. This is because capacitive loads tend to draw more current than inductive loads, resulting in an increase in the total reactive power demand. By using an SVG, the amount of capacitive reactive power can be reduced, allowing the system to operate more efficiently and reducing losses.

Any technical inquiry about Static Var Generator(SVG) or Active Harmonic Filter(AHF), contact with us sales@yt-electric.com

Subscribe to us to enjoy event prices and get some of the best prices.

IPv6 network supported

IPv6 network supported