A 150A Active Harmonic Filter (AHF) module is a specific type of AHF designed to handle and compensate power quality up to 150 amperes. This module is used to improve power quality by reducing harmonic distortion,compensation reactive power and unbalance in electrical systems. Here’s a detailed overview of its installations, features, working principles, applications, and benefits:

The installation of Active Harmonic Filter (AHF) modules can vary based on the application, system configuration, and specific requirements of the electrical system. Here are the common installation types and considerations for AHF modules:

1.Wall-Mounted Installation

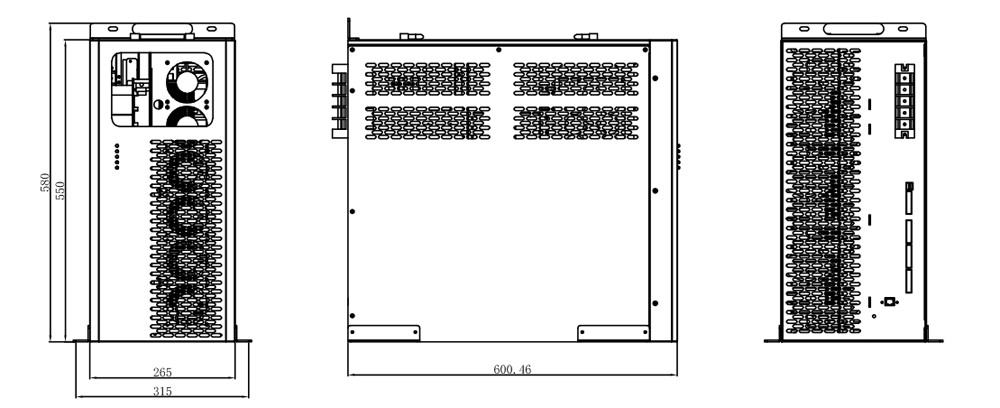

Description: AHFs can be installed on walls, especially in areas with limited floor space.

Applications: Suitable for smaller systems or when the AHF is used to filter harmonics for a specific load or section of a facility.

Considerations: Ensure the wall can support the weight of the AHF module and provides adequate ventilation.

2. Floor-Mounted Installation

Description: AHFs can be mounted on the floor, typically in a dedicated electrical room or near the main distribution panels.

Applications: Suitable for larger systems or facilities with multiple harmonic-generating loads.

Considerations: Ensure the floor can bear the weight and provide enough clearance for ventilation and maintenance access.

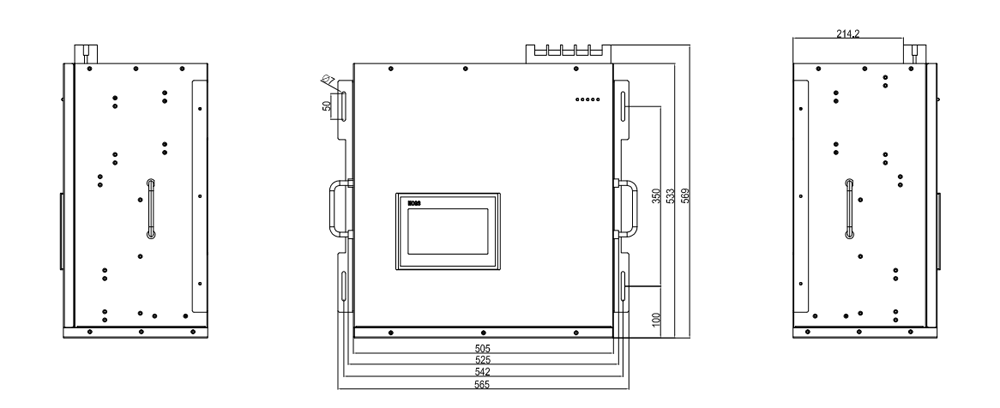

3. Panel or Cabinet Installation

Description: AHFs can be integrated into existing electrical panels or housed in standalone cabinets.

Applications: Ideal for new installations or upgrades where the AHF needs to be integrated with other electrical components.

Considerations: Ensure proper integration with the panel design and sufficient space for ventilation and cooling.

4. Rack-Mounted Installation

Description: AHFs can be mounted in standard 19-inch racks, commonly used in data centers and IT environments.

Applications: Suitable for data centers and environments where rack space is available.

Considerations: Ensure adequate cooling and accessibility for maintenance within the rack system.

Consider a manufacturing plant with several large motors and VFDs. These devices generate significant harmonic currents, leading to voltage distortion and potential issues with sensitive equipment.

In summary, a 150A Active Harmonic Filter module is a powerful tool for improving power quality in systems with significant harmonic currents. By dynamically compensating for harmonics, it enhances system efficiency, protects equipment, and ensures compliance with power quality standards.

1. Location Selection

Choose a location that is close to the main source of harmonics or the point of common coupling (PCC) in the power system.

Ensure the location provides easy access for installation, maintenance, and monitoring.

2. Ventilation and Cooling

AHFs generate heat during operation, so adequate ventilation or cooling systems must be in place.

Ensure there is sufficient airflow around the AHF module to prevent overheating.

3. Electrical Connections

Connect the AHF module to the power system according to the manufacturer’s instructions, typically involving connections to the supply bus and load bus.

Use appropriately rated cables and protection devices to ensure safe and reliable operation.

4. Grounding and Bonding

Proper grounding and bonding are essential for the safe operation of AHF modules.

Follow the manufacturer’s guidelines and local electrical codes for grounding requirements.

5. Protection and Safety

Install overcurrent protection devices (e.g., fuses or circuit breakers) to protect the AHF module and the electrical system.

Ensure compliance with all relevant safety standards and regulations.

6. Communication and Integration

If the AHF module includes communication capabilities, integrate it with the building management system (BMS) or energy management system (EMS) for remote monitoring and control.

Configure communication protocols as required, such as Modbus, Ethernet, or other specified protocols.

1. Site Assessment and Planning

Conduct a thorough site assessment to understand the harmonic levels and identify the optimal installation points.

Develop an installation plan considering the electrical layout, ventilation, and accessibility.

2. Preparation

Prepare the installation site by ensuring it is clean, clear of obstructions, and meets all structural and electrical requirements.

Verify that all necessary tools and materials are available.

3. Mechanical Installation

Mount the AHF module on the wall, floor, panel, or rack as planned.

Secure the module in place using appropriate mounting hardware.

4. Electrical Installation

Make the necessary electrical connections to the power system, following the manufacturer’s wiring diagram and local electrical codes.

Connect the control and communication cables as required.

5. Commissioning

Power up the AHF module and perform initial checks to ensure proper operation.

Configure the module settings, including harmonic compensation levels, protection parameters, and communication settings.

Test the system to verify that the AHF module effectively mitigates harmonics and improves power quality.

6. Monitoring and Maintenance

Regularly monitor the performance of the AHF module through the user interface or integrated communication system.

Schedule periodic maintenance to clean, inspect, and test the module to ensure ongoing reliable operation.

In summary, the installation of AHF modules involves careful planning, proper site preparation, and adherence to manufacturer guidelines and local electrical codes. By selecting the appropriate installation type and ensuring all necessary considerations are addressed, you can effectively deploy AHF modules to improve power quality and protect your electrical system.

Subscribe to us to enjoy event prices and get some of the best prices.

IPv6 network supported

IPv6 network supported