Jiangsu Non Woven was founded in 2002 and has a 20-year history of non-woven fabric production, which is a high-quality manufacturer of high-end non-woven fabrics integrating R&D, production and after-sales. The factory is located in Zhitang Town, Changshu City, Jiangsu Province, a famous non-woven fabric production base in China, covering an area of 15,000 square meters, with a daily production capacity of 40 tons, producing a variety of staple fiber non-woven fabrics, including melt-blown non-woven fabrics, synthetic leather base fabrics, needle-punched non-woven fabrics, polypropylene non-woven fabrics, absorbent pads, filtering non-woven fabrics, antibacterial cotton, automotive interior materials, oil absorbent pads and other non-woven products. The products are widely used in medicine, automobiles, leather, sports shoes, home textiles, smart home and other fields.

The factory equipment mainly includes carding machines, needle punching machines, non-woven ovens, rolling machines, etc., which will generate a large number of harmonics in the production process, resulting in the on-site capacitance compensation cabinet not working normally, and often capacitor bulging and contactor burnout. In order to ensure the normal operation of the on-site capacitive cabinet, a 300A active filter cabinet is installed on site for harmonic control.

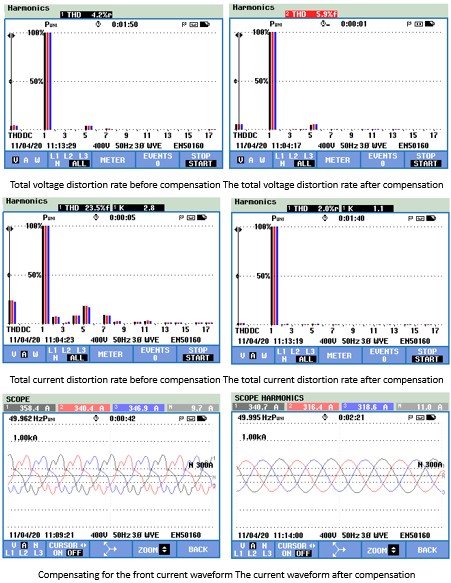

The on-site voltage distortion rate is 5.9%, exceeding the national standard limit of 5%, the current distortion rate is 23.5%, and the harmonic current is mainly 3rd and 5th harmonics, and also contains a small amount of 2nd and 4th even harmonics. After treatment, the voltage distortion rate was reduced to 4.2%, and the current distortion rate was reduced to 2.0%, and the on-site capacitor compensation cabinet could operate normally without operational failures.

Subscribe to us to enjoy event prices and get some of the best prices.

IPv6 network supported

IPv6 network supported