Commercial centers in Spain face unique electrical challenges due to modern infrastructure demands. These facilities integrate high-power HVAC systems, extensive LED lighting, and numerous electric vehicle charging stations. Such diverse loads often lead to significant power quality degradation if left unmanaged.

This case study examines a major Spanish retail hub experiencing frequent equipment failures. Technical analysis revealed high harmonic distortion and voltage fluctuations as the primary culprits. Addressing these issues requires a systematic approach to ensure operational stability and energy efficiency.

The initial site survey identified significant non-linear loads throughout the shopping complex. Variable frequency drives in the cooling systems were generating substantial harmonic currents. These harmonics caused overheating in transformers and unexpected tripping of circuit breakers.

Voltage sags were also recorded during peak operating hours in the afternoon. These dips affected the sensitive point-of-sale systems and digital signage across the facility. Without stable power, the commercial center faced potential revenue loss and high maintenance costs.

Our engineering team deployed power quality analyzers at the main distribution boards. We monitored total harmonic distortion (THD) and power factor over a seven-day period. The data showed that current THD exceeded 25% during maximum load conditions.

| Parameter | Measured Value | Standard Limit (IEEE 519) | Status |

| Current THD | 27.4% | < 8.0% | Critical |

| Voltage THD | 6.2% | < 5.0% | Warning |

| Power Factor | 0.82 | > 0.95 | Low |

The table above illustrates the gap between current performance and international standards. High harmonic levels were clearly shortening the lifespan of the center's electrical components. Improving these metrics was essential for long-term reliability and reducing electricity penalties.

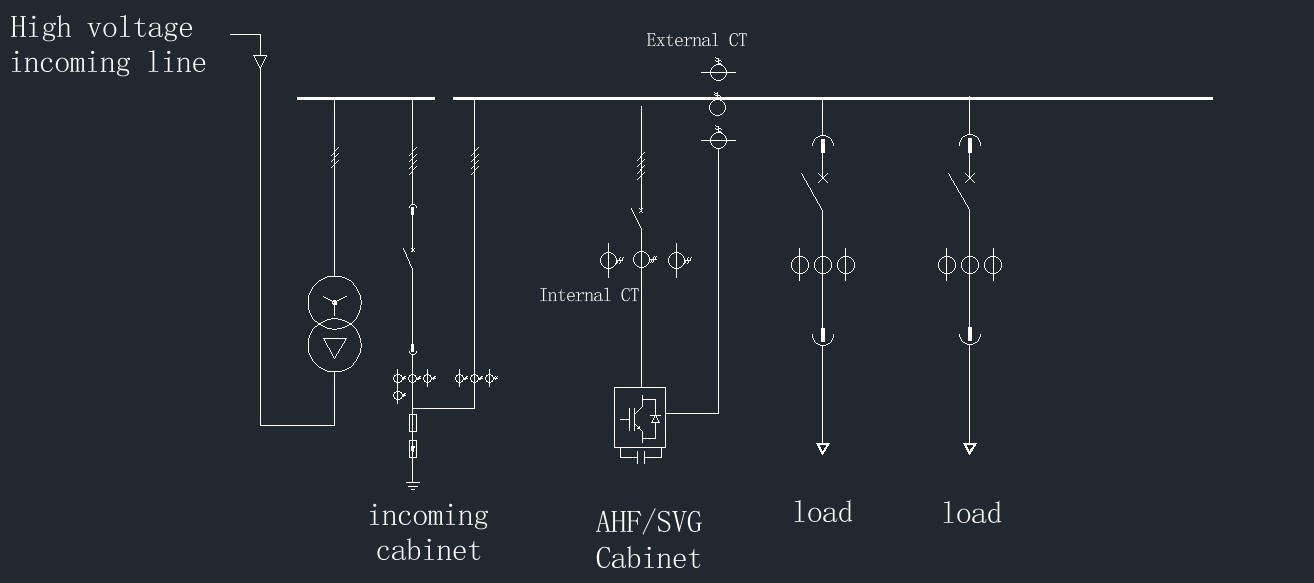

To mitigate these issues, we installed Active Power Filters (APF) at the primary sub-stations. Unlike passive filters, APFs adapt to changing load conditions in real-time. They inject compensating currents to cancel out harmonics and improve the overall power factor.

We also integrated a centralized monitoring system to track energy consumption patterns. This allows the facility management team to identify anomalies before they lead to failure. The real-time data provides a clear view of the electrical health of the building.

Following the installation, the electrical environment showed immediate and measurable improvement. Current THD dropped significantly, falling well within the recommended safety margins. The stabilized voltage levels eliminated the frequent resetting of sensitive electronic equipment.

| Metric Post-Installation | Previous Value | New Value | Improvement |

| Current THD | 27.4% | 4.1% | 85% Reduction |

| Power Factor | 0.82 | 0.98 | 19% Increase |

| Equipment Downtime | High | Negligible | 100% Stability |

The commercial center now operates with much higher energy efficiency. Lower heat generation in the cables and transformers has reduced the cooling load in electrical rooms. This cascading benefit further lowers the total utility costs for the property owners.

Managing power quality is a necessity for modern Spanish commercial centers. Regular audits and the use of active mitigation technology prevent costly hardware replacements. Proactive monitoring ensures that the electrical infrastructure can support future expansion.

We recommend that facility managers perform power quality assessments every two years. Integrating surge protection and harmonic filtering creates a resilient electrical foundation. This approach protects both the business reputation and the physical assets of the center.

Subscribe to us to enjoy event prices and get some of the best prices.

IPv6 network supported

IPv6 network supported