Harmonic Distortion Explained: Dangers of High Levels & How to Protect Your Systems

Harmonic distortion is a hidden threat in modern electrical systems. While it doesn't get the same attention as power outages or surges, excessive harmonic distortion can quietly damage equipment, reduce energy efficiency, and cost businesses thousands.

Understanding what harmonic distortion is, why it happens, and how to protect your systems is essential for any facility manager, engineer, or business owner.

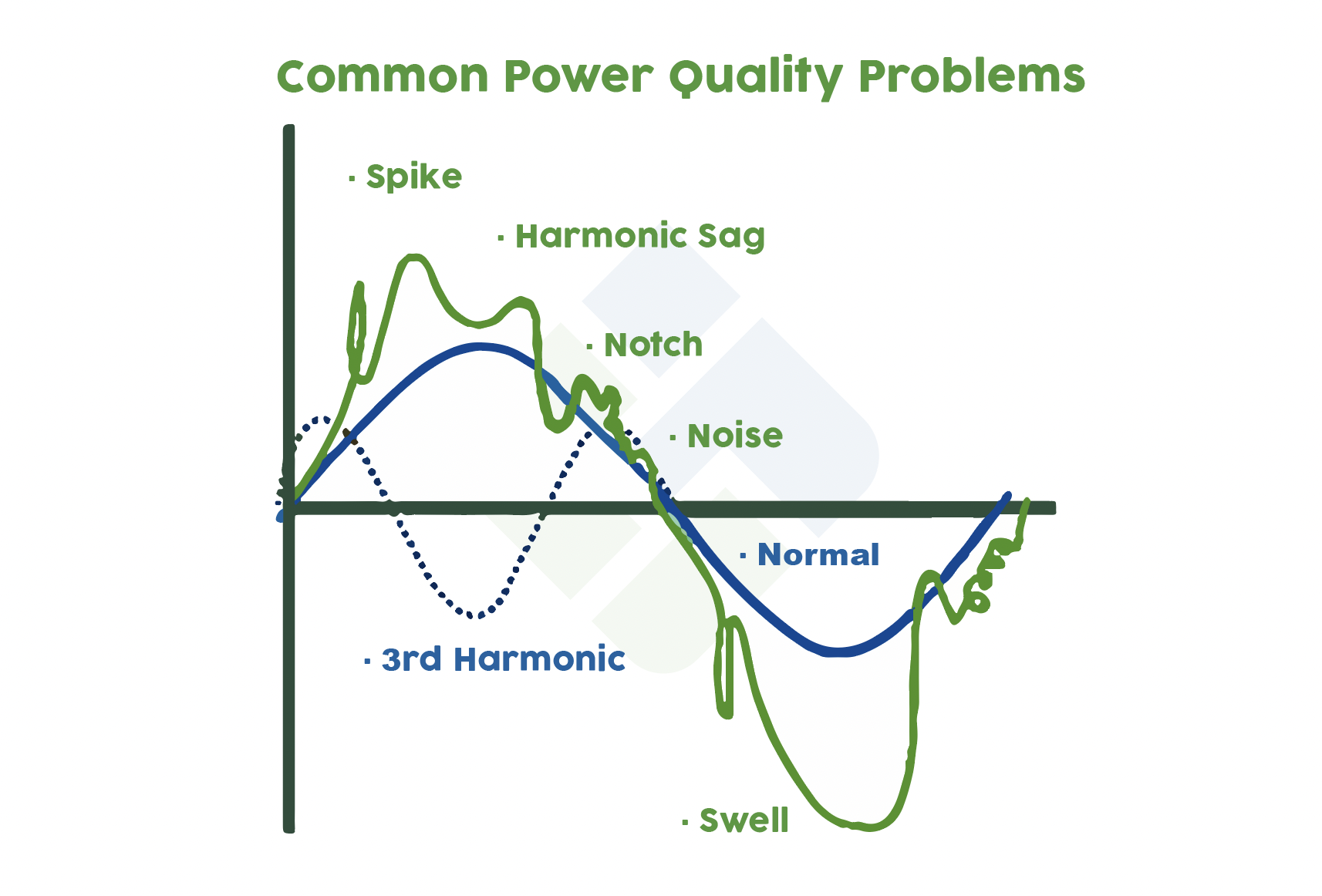

In an ideal electrical system, voltage and current waveforms follow a perfect sine wave. Harmonics are voltage or current components at multiples of the fundamental frequency (typically 50 or 60 Hz). When these harmonics are introduced into a system, they distort the original waveform. This is what we call harmonic distortion.

Total Harmonic Distortion (THD) is a measure of how much the waveform deviates from the ideal. THD is usually expressed as a percentage: the higher the THD, the greater the distortion.

Harmonics are most often caused by non-linear loads—devices that draw current in abrupt pulses rather than smooth, sinusoidal waves. Common culprits include:

- Variable frequency drives (VFDs)

- UPS systems

- LED lighting

- Computers and office equipment

- EV chargers

As industries adopt more energy-efficient and electronically controlled devices, the level of harmonic distortion in power systems has steadily increased.

High THD is not just a technical anomaly. It has real consequences:

Transformers, motors, and cables can overheat due to increased current flow caused by harmonics. This reduces equipment lifespan and increases the risk of failure.

Harmonics lower the power factor of a system, making it less efficient. Utilities may penalize low power factor performance, leading to higher bills.

Medical devices, control systems, and communication equipment can malfunction in high-harmonic environments. This is particularly critical in hospitals, data centers, and industrial plants.

Distorted waveforms mean your system has to work harder to deliver the same amount of power. That inefficiency translates directly into higher energy consumption.

Harmonics can resonate with the system’s natural frequency, amplifying voltages or currents and causing unexpected failures.

You can’t fix what you can’t measure. Here are common ways to detect and quantify harmonics:

Facility managers should include harmonic assessments in regular maintenance schedules, especially in high-tech or heavily automated environments.

Active Harmonic Filters are designed to eliminate specific harmonic frequencies, more flexible and effective for variable loads.

YTPQC-AHFs filter 2-50th odd harmonic, 100% of rated capacity.

- Voltage level: 220V~800V

- 3P3W/3P4W

- 50/60Hz

- Rack/Wall-mounted/Cabinet

At YT Electric, we specialize in harmonic analysis and mitigation strategies tailored to your facility. Whether you're operating a manufacturing plant, hospital, or office building, we offer solutions to help you maintain power quality, extend equipment life, and save on energy costs.

Understanding, detecting, and mitigating harmonic distortion is not just good practice—it’s essential for protecting your investment and ensuring long-term system reliability. Take proactive steps now to ensure your systems are protected.

YT Electric is the biggest OEM manufacturer of low-voltage AHF and SVG with more than 15 years' experience. All products hold certifications for ISO9001, CE, and CQC standards, and type test reports support them.

For more information on how our AHFs can help manage harmonics and improve power quality: contact us at sales@yt-electric.com.

Subscribe to us to enjoy event prices and get some of the best prices.

IPv6 network supported

IPv6 network supported