EMC (Electromagnetic Compatibility) testing for an Active Harmonic Filter AHF is critical and non-negotiable. An AHF(APF) is a power electronics device (like a high-frequency inverter) that injects canceling currents into a noisy electrical system. If poorly designed, it can become a significant source of electromagnetic interference (EMI) itself, disrupting other equipment. Conversely, it must be immune to the electromagnetic pollution present in industrial environments to operate reliably.

Testing verifies two main properties:

EMI (Emission): That the AHF does not emit excessive interference into the power lines or radiate into space.

Immunity (Susceptibility): That the AHF continues to operate correctly when subjected to external interference like surges, dips, and RF fields.

AHFs fall under the umbrella of "Industrial Equipment" and are primarily tested against the following standards:

Generic Standard for Industrial Environments: EN/IEC 61000-6-4 (Emission)

Generic Standard for Industrial Environments: EN/IEC 61000-6-2 (Immunity)

These generic standards often reference more specific "basic" standards for the test methods.

EN 61000-3-12: Limits for harmonic currents produced by equipment connected to public low-voltage systems with input current >16A and ≤75A per phase. (Often a key standard for AHFs).

EN 61000-3-2: For equipment with input current ≤16A per phase.

EN 61800-3: Adjustable speed electrical power drive systems. This is highly relevant as the core of an AHF is a PWM-driven inverter, similar to a variable frequency drive (VFD).

Testing is divided into two main categories: Emissions and Immunity.

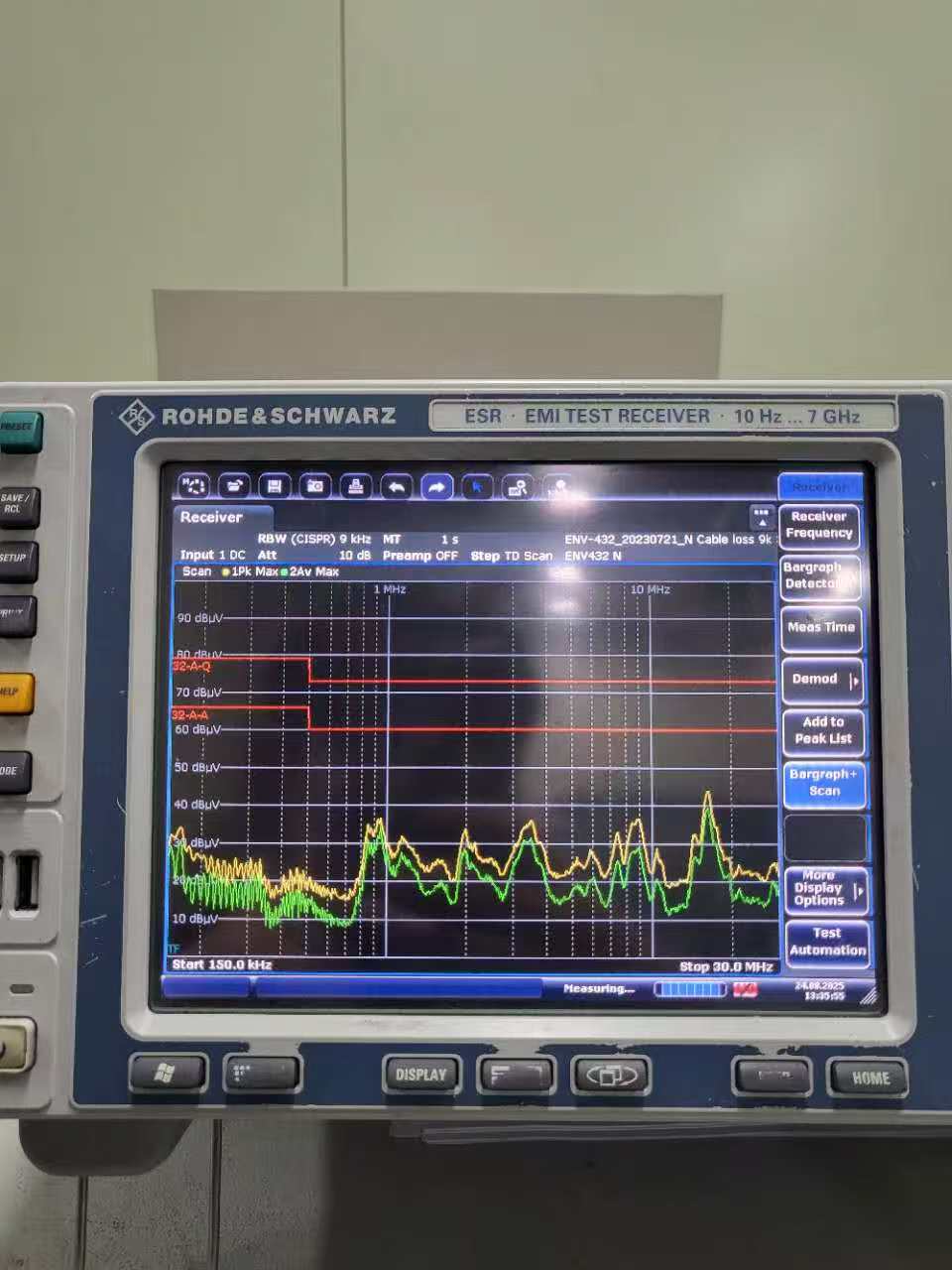

Conducted Emissions (CE)

What it is: Measures high-frequency noise (150 kHz - 30 MHz) that the AHF sends back into the power grid through its supply terminals.

Why it matters: This noise can travel far within a facility, causing malfunctions in sensitive equipment like PLCs, sensors, and communication devices connected to the same power network.

Test Setup: The AHF is powered and operating at full load in a test chamber. A Line Impedance Stabilization Network (LISN) is inserted between the power source and the AHF. The LISN provides a standardized impedance and allows a spectrum analyzer to measure the noise voltage on the power lines.

Radiated Emissions (RE)

What it is: Measures the electromagnetic field (30 MHz - 1 GHz, often up to 6 GHz) that the AHF radiates through the air from its enclosure, cables, and heat sinks.

Why it matters: This radio frequency noise can interfere with nearby wireless devices (radios, WiFi, Bluetooth) and other electronic equipment.

Test Setup: The AHF operates in a semi-anechoic chamber or an open area test site (OATS). An antenna placed at a standard distance (3m, 10m, or 30m) scans for the strongest emissions from the unit.

Harmonic Current Emissions (EN 61000-3-12)

What it is: Measures the low-frequency current harmonics (up to the 40th harmonic, ~2 kHz) that the AHF itself draws from the mains. Note: This is different from the harmonic currents it is meant to cancel. Even a "filter" has a power supply and control circuitry that can create distortion.

Why it matters: Ensures the AHF does not contribute to the fundamental harmonic pollution problem it's installed to solve.

Test Setup: A precision power analyzer measures the input current waveform and performs a Fourier analysis to calculate the magnitude of each harmonic component.

Electrostatic Discharge (ESD) - IEC 61000-4-2

What it is: Simulates a person walking on a carpet and touching the equipment or a discharge between two objects.

Why it matters: Tests the robustness of the human machine interface(HMI), communication ports, and overall shielding. Should not reset or damage the unit.

Electrical Fast Transient/Burst (EFT) - IEC 61000-4-4

What it is: Injects a series of very fast, high-voltage spikes onto the power and I/O lines. These are common from inductive load switching (relays, contactors, motors).

Why it matters: A very severe test for the AHF's power supply and control circuitry. Must not malfunction or trip erroneously.

Surge Immunity - IEC 61000-4-5

What it is: Simulates high-energy transients from lightning strikes on external lines or major load switching.

Why it matters: Critical for equipment connected to long power lines in industrial settings. Tests the robustness of the input stage and surge protection devices (MOVs).

Voltage Dips, Short Interruptions, and Variations - IEC 61000-4-11

What it is: Simulates brownouts (voltage dips), brief blackouts (interruptions), and voltage fluctuations on the mains.

Why it matters: The AHF should ride through short dips, restart gracefully after brief interruptions, and not inject erroneous currents during the event.

Radiated RF Immunity - IEC 61000-4-3

What it is: The AHF is exposed to a powerful, modulated RF field inside a chamber.

Why it matters: Simulates interference from nearby radio transmitters, walkie-talkies, etc. The AHF should not have its measurements corrupted or controls disrupted.

Conducted RF Immunity - IEC 61000-4-6

Test Modes: The Active Harmonic Filter must be tested in its worst-case emission scenario. This is typically at full load, with a non-linear load creating strong harmonics, and with the AHF's compensation gain set to maximum. For immunity, test in a sensitive mode where it is actively measuring and compensating.

Layout & Cabling: EMC performance is highly dependent on internal PCB layout, grounding, and filtering. External cabling (CT sensor wires, power cables) are prime antennas. Tests should be done with representative cable lengths and routing.

Performance Criteria: During immunity tests, it's not always required to perform perfectly. Standards define performance criteria (e.g., Criteria A: normal performance within specification; Criteria B: temporary degradation or loss of function that self-recovers). For an AHF, a temporary stop in filtering (B) might be acceptable, but a permanent lockup or damage is not.

Pre-Compliance Testing: To save time and cost, manufacturers often perform pre-compliance tests in-house with smaller, more affordable equipment to identify and fix major issues before going to an accredited EMC test lab for formal certification.

A successful EMC test report for an Active Harmonic Filter is a powerful mark of quality and reliability. It proves that the device is a true solution, not a new problem. It assures the customer that the AHF will:

Survive the harsh electrical environment of an industrial plant.

Perform its filtering function without being disrupted by interference.

Coexist peacefully with other sensitive equipment on the network.

Subscribe to us to enjoy event prices and get some of the best prices.

IPv6 network supported

IPv6 network supported