In the power quality industry, real manufacturing capability matters. Beyond product specifications and brochures, customers increasingly want to understand how and where equipment is actually built. This article, together with our factory production video, offers a transparent look inside YT Electric’s manufacturing facility, highlighting our in-house production of core components, professional welding processes, and the experienced technical team behind every system we deliver.

YT Electric is not a trading company. We are a source manufacturer specializing in power quality solutions, with critical processes completed entirely within our own factory.

Power quality equipment such as SVG (STATCOM) and Active Harmonic Filters (AHF/APF) operates continuously under demanding electrical and environmental conditions. Long-term stability, fast response, and system reliability depend heavily on the quality of internal components and manufacturing consistency.

For this reason, YT Electric follows a clear principle:

Key components and core control units must be designed and produced in-house.

By keeping critical processes under our direct control, we reduce dependency on external suppliers, ensure consistent quality, and maintain full responsibility for product performance throughout the equipment lifecycle.

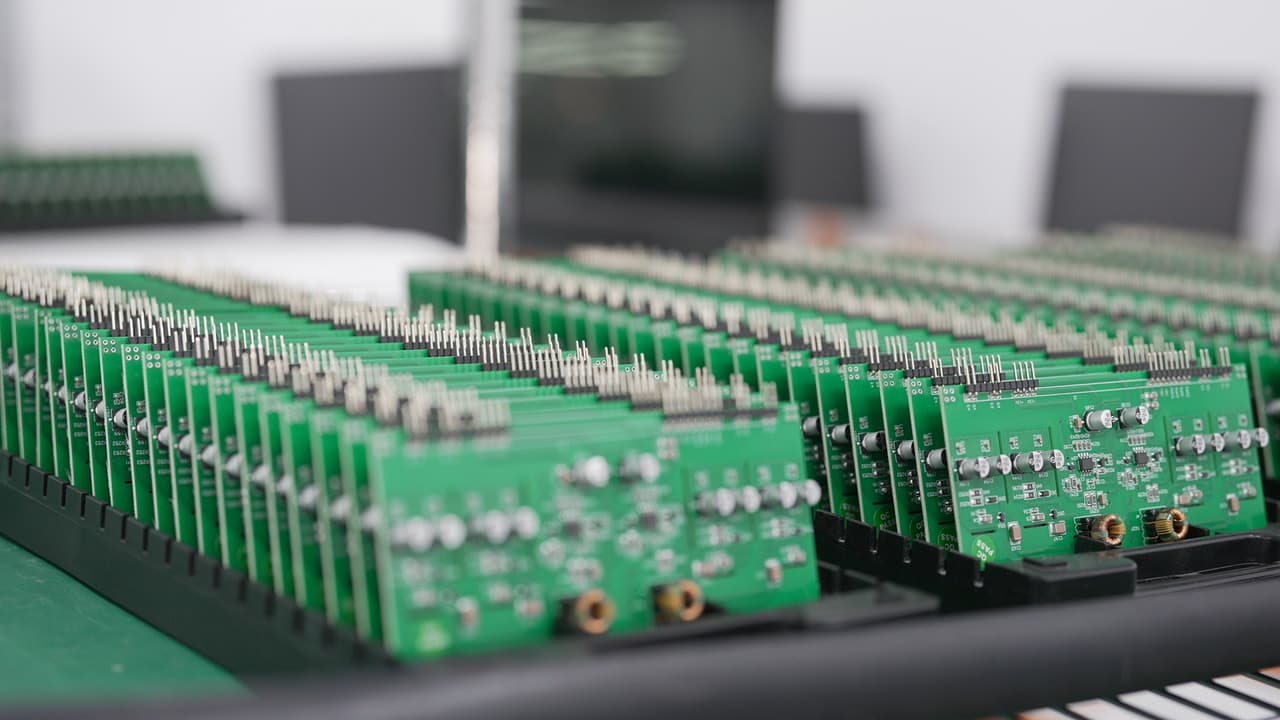

The control system is the “brain” of SVG and STATCOM equipment. At YT Electric, core control unit boards are developed and produced internally, allowing us to:

Optimize hardware and control algorithms as a complete system

Ensure precise matching between control boards and power modules

Support customized solutions for different grid conditions and project requirements

Provide long-term technical support and upgrade capability

Internal production also enables faster response for customization and after-sales service, a key advantage for B2B customers operating mission-critical power systems.

In addition to control boards, YT Electric strictly manages the selection, assembly, and testing of critical electrical components. Each key module undergoes functional verification before integration, ensuring stable performance under long-term industrial operation.

The factory video highlights one of the most important but often overlooked aspects of power equipment manufacturing: structural welding quality.

YT Electric is equipped with professional industrial welding machines and standardized welding procedures suitable for:

Power cabinet frames

Structural supports

High-current connection points

Proper welding directly affects mechanical strength, electrical safety, and service life. Our standardized welding process ensures solid structure, clean connections, and reliable performance in harsh industrial environments.

Advanced equipment alone is not enough. The quality seen in our production process is the result of experienced technicians and welders who work with power quality equipment on a daily basis.

Our team advantages include:

Long-term, stable production staff rather than temporary labor

Hands-on experience with SVG, STATCOM, and harmonic filtering systems

Clear division of responsibilities across assembly, welding, and testing stages

This combination of skilled personnel and standardized processes ensures consistent manufacturing quality from one project to the next.

Every production stage at YT Electric is supported by internal quality checks. From welded structures to control units and integrated systems, inspections are conducted to confirm compliance with design requirements before equipment leaves the factory.

This multi-stage quality control approach reduces installation risks, minimizes commissioning time, and improves long-term system reliability for our customers.

YT Electric’s manufacturing capability directly supports projects across Southeast Asia, India, Europe, and other international markets. Our in-house production model provides a strong foundation for delivering stable, customized, and reliable power quality solutions worldwide.

The factory video represents our daily production reality—not a staged demonstration. It reflects the equipment, people, and processes behind every YT Electric system.

Reliable power quality solutions begin with real manufacturing strength. Through in-house production of core components, professional welding equipment, and a skilled technical team, YT Electric ensures that every SVG, STATCOM, and harmonic filtering system meets high industrial standards.

To learn more about our products and manufacturing capabilities, please visit our official website:

For technical inquiries, project discussions, or partnership opportunities, our team is ready to support you.

Subscribe to us to enjoy event prices and get some of the best prices.

IPv6 network supported

IPv6 network supported