In today’s world, where industries rely heavily on electronic equipment and non-linear loads, maintaining power quality has become a critical concern. Poor power quality can lead to inefficiencies, equipment damage, and increased operational costs. One of the most effective solutions to address power quality issues, particularly harmonic distortion, is the use of Active Harmonic Filters (AHFs). In this blog, we’ll explore what an Active Harmonic Filter is, how it works, its benefits, and why it’s an essential component of modern power quality solutions.

Understanding Harmonics and How They Affect Things

Understanding what harmonics are and why they are troublesome is crucial before delving into Active Harmonic Filters. Electrical waveform distortions known as harmonics are turned on by non-linear loads like computers, LED lights, variable frequency drives (VFDs), and other electronic equipment. These loads produce harmonic frequencies that are multiples of the basic power frequency (50 Hz or 60 Hz) by drawing current in brief pulses as opposed to a smooth sinusoidal wave.

Harmonics can cause several issues, including:

Overheating of equipment: Harmonics increase the RMS current, leading to excessive heat in transformers, motors, and cables.

Voltage distortion: Harmonics can distort the voltage waveform, affecting the performance of sensitive equipment.

Power losses: Increased harmonic currents result in higher energy losses and reduced system efficiency.

Nuisance tripping: Harmonics can cause circuit breakers and protective devices to trip unnecessarily.

Interference: Harmonics can interfere with communication systems and other electronic devices.

To mitigate these issues, harmonic filters are used. Among the various types of filters available, Active Harmonic Filters are considered one of the most advanced and effective solutions.

What is an Active Harmonic Filter?

An Active Harmonic Filter (AHF) is an electronic device designed to mitigate harmonic distortion in electrical systems. Unlike passive filters, which use passive components like capacitors and inductors to block or absorb harmonics, AHFs use power electronics to actively inject counter-harmonic currents into the system. This cancels out the harmonic currents generated by non-linear loads, resulting in a cleaner and more stable power supply.

How Does an Active Harmonic Filter Work?

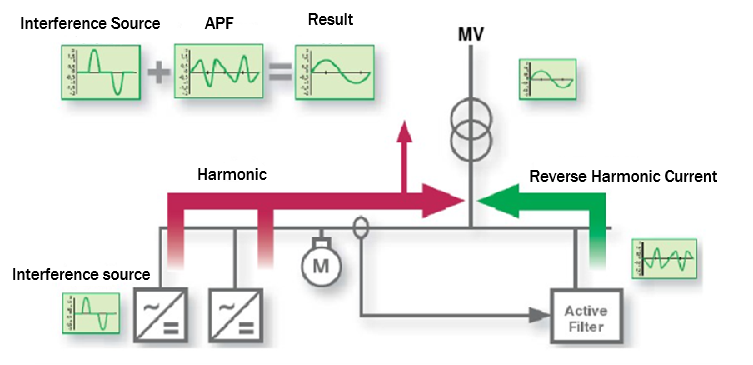

The operation of an Active Harmonic Filter can be broken down into the following steps:

Monitoring the Load Current: The AHF continuously monitors the load current using sensors. It analyzes the waveform to detect harmonic frequencies.

Harmonic Detection: Using advanced algorithms and digital signal processing (DSP), the AHF identifies the harmonic components present in the load current.

Generating Counter-Harmonics: The AHF generates harmonic currents that are equal in magnitude but opposite in phase to the detected harmonics.

Injecting Counter-Harmonics: The generated counter-harmonic currents are injected back into the electrical system. This effectively cancels out the harmonic distortion, resulting in a sinusoidal current waveform.

Real-Time Adjustment: AHFs operate in real-time, continuously adapting to changes in the load and harmonic profile to ensure optimal performance.

Working Principle:

Key Benefits of Active Harmonic Filters:

Active Harmonic Filters offer several advantages over traditional passive filters and other harmonic mitigation techniques:

High Efficiency: AHFs can reduce harmonic distortion to less than 5%, ensuring compliance with international standards like IEEE 519 and IEC 61000.

Dynamic Performance: Unlike passive filters, which are tuned to specific frequencies, AHFs can mitigate a wide range of harmonic frequencies, making them suitable for diverse applications.

Compact Design: AHFs are typically smaller and lighter than passive filters, making them easier to install in space-constrained environments.

Reactive Power Compensation: Many AHFs also provide reactive power compensation, improving the power factor and reducing energy costs.

Scalability: AHFs can be easily scaled to meet the needs of growing systems or changing load conditions.

Reduced Maintenance: With no passive components like capacitors or inductors, AHFs require minimal maintenance and have a longer lifespan.

Applications of Active Harmonic Filters

Active Harmonic Filters are widely used in industries and facilities where harmonic distortion is a concern. Some common applications include:

Industrial Plants: Facilities with heavy machinery, VFDs, and other non-linear loads.

Data Centers: Sensitive electronic equipment that requires clean and stable power.

Healthcare Facilities: Hospitals and clinics with advanced medical equipment.

Commercial Buildings: Offices, shopping malls, and hotels with LED lighting and HVAC systems.

Renewable Energy Systems: Solar and wind power installations with inverters that generate harmonics.

Subscribe to us to enjoy event prices and get some of the best prices.

IPv6 network supported

IPv6 network supported